Quality Control and Assurance Policy Template

Document content

This quality control and assurance policy template has 4 pages and is a MS Word file type listed under our human resources documents.

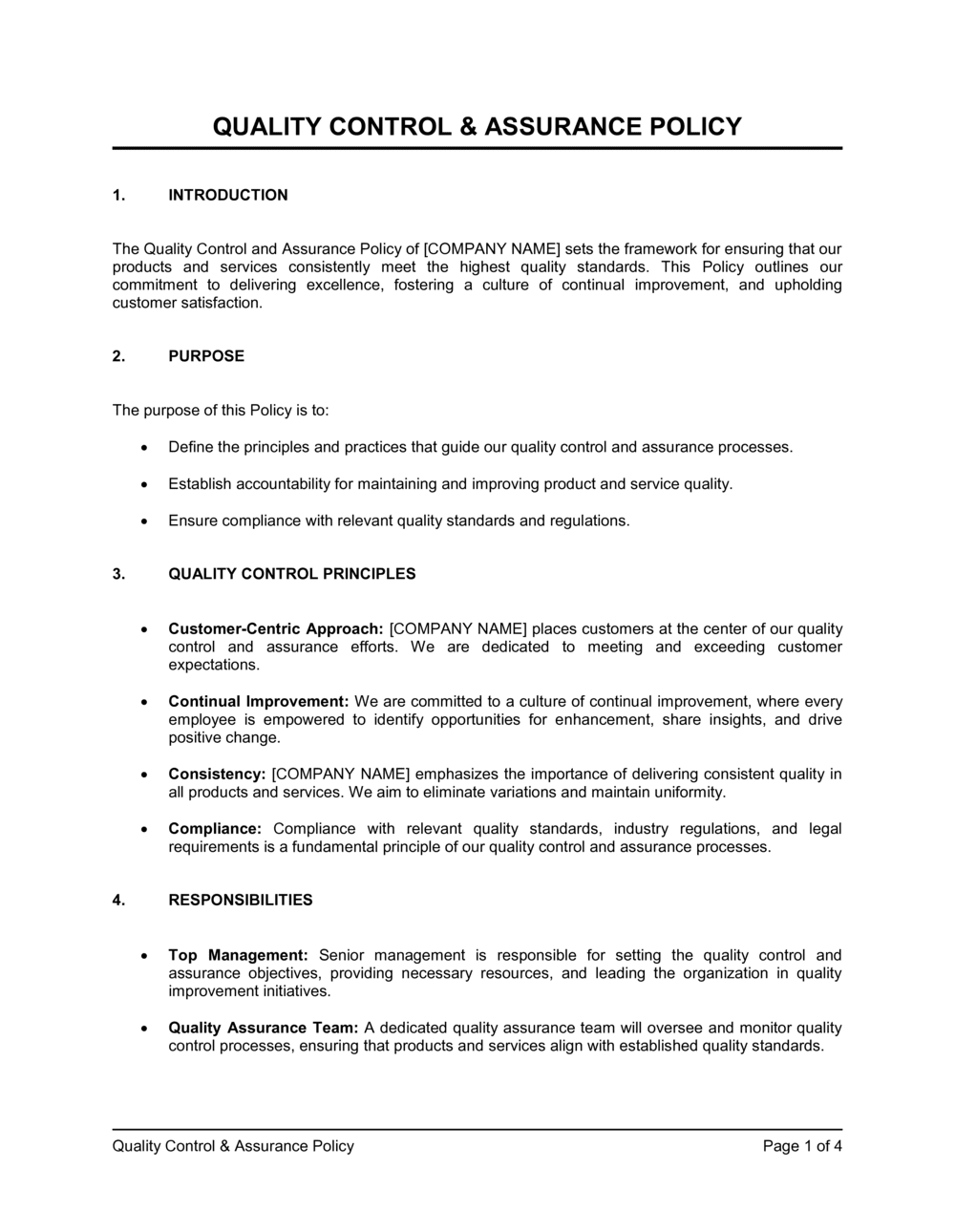

Sample of our quality control and assurance policy template:

QUALITY CONTROL & ASSURANCE POLICY INTRODUCTION The Quality Control and Assurance Policy of [COMPANY NAME] sets the framework for ensuring that our products and services consistently meet the highest quality standards. This Policy outlines our commitment to delivering excellence, fostering a culture of continual improvement, and upholding customer satisfaction. PURPOSE The purpose of this Policy is to: Define the principles and practices that guide our quality control and assurance processes. Establish accountability for maintaining and improving product and service quality. Ensure compliance with relevant quality standards and regulations. QUALITY CONTROL PRINCIPLES Customer-Centric Approach: [COMPANY NAME] places customers at the center of our quality control and assurance efforts. We are dedicated to meeting and exceeding customer expectations. Continual Improvement: We are committed to a culture of continual improvement, where every employee is empowered to identify opportunities for enhancement, share insights, and drive positive change. Consistency: [COMPANY NAME] emphasizes the importance of delivering consistent quality in all products and services. We aim to eliminate variations and maintain uniformity. Compliance: Compliance with relevant quality standards, industry regulations, and legal requirements is a fundamental principle of our quality control and assurance processes. RESPONSIBILITIES Top Management: Senior management is responsible for setting the quality control and assurance objectives, providing necessary resources, and leading the organization in quality improvement initiatives. Quality Assurance Team: A dedicated quality assurance team will oversee and monitor quality control processes, ensuring that products and services align with established quality standards. Employees: All employees have a shared responsibility for maintaining quality. They are encouraged to proactively identify and report quality issues and actively participate in improvement initiatives. QUALITY CONTROL PROCESSES Quality control is an essential component of maintaining product and service quality. Here's an expansion on this section: Product Inspections: [COMPANY NAME] will implement systematic product inspections to ensure that each unit or batch meets our established quality standards. These inspections will be conducted at various stages of production or service delivery to identify any deviations from our quality criteria. Testing: Testing procedures will be employed to verify that products or services meet specific quality benchmarks. These tests may include performance evaluations, durability tests, safety assessments, or other relevant criteria, depending on the nature of the product or service. Validation: Validation processes will be used to ensure that products and services are aligned with customer requirements and quality standards. This may involve customer sign-offs, product testing against specifications, and adherence to regulatory guidelines. Regular Monitoring: Regular monitoring of quality control processes will be conducted to track performance and identify trends. This continual assessment allows [COMPANY NAME] to detect quality issues early and take corrective actions promptly. Data Collection: Data related to quality control will be systematically collected, organized, and analyzed. This data may include information on product specifications, testing results, inspection reports, and customer feedback. Corrective Actions: In cases where deviations from quality standards are identified, corrective actions will be triggered. These actions may involve process adjustments, rework, or further testing to address and prevent quality issues. Corrective actions will be documented for future reference and process improvement. QUALITY ASSURANCE MEASURES

3,000+ Templates & Tools to Help You Start, Run & Grow Your Business

Document content

This quality control and assurance policy template has 4 pages and is a MS Word file type listed under our human resources documents.

Sample of our quality control and assurance policy template:

QUALITY CONTROL & ASSURANCE POLICY INTRODUCTION The Quality Control and Assurance Policy of [COMPANY NAME] sets the framework for ensuring that our products and services consistently meet the highest quality standards. This Policy outlines our commitment to delivering excellence, fostering a culture of continual improvement, and upholding customer satisfaction. PURPOSE The purpose of this Policy is to: Define the principles and practices that guide our quality control and assurance processes. Establish accountability for maintaining and improving product and service quality. Ensure compliance with relevant quality standards and regulations. QUALITY CONTROL PRINCIPLES Customer-Centric Approach: [COMPANY NAME] places customers at the center of our quality control and assurance efforts. We are dedicated to meeting and exceeding customer expectations. Continual Improvement: We are committed to a culture of continual improvement, where every employee is empowered to identify opportunities for enhancement, share insights, and drive positive change. Consistency: [COMPANY NAME] emphasizes the importance of delivering consistent quality in all products and services. We aim to eliminate variations and maintain uniformity. Compliance: Compliance with relevant quality standards, industry regulations, and legal requirements is a fundamental principle of our quality control and assurance processes. RESPONSIBILITIES Top Management: Senior management is responsible for setting the quality control and assurance objectives, providing necessary resources, and leading the organization in quality improvement initiatives. Quality Assurance Team: A dedicated quality assurance team will oversee and monitor quality control processes, ensuring that products and services align with established quality standards. Employees: All employees have a shared responsibility for maintaining quality. They are encouraged to proactively identify and report quality issues and actively participate in improvement initiatives. QUALITY CONTROL PROCESSES Quality control is an essential component of maintaining product and service quality. Here's an expansion on this section: Product Inspections: [COMPANY NAME] will implement systematic product inspections to ensure that each unit or batch meets our established quality standards. These inspections will be conducted at various stages of production or service delivery to identify any deviations from our quality criteria. Testing: Testing procedures will be employed to verify that products or services meet specific quality benchmarks. These tests may include performance evaluations, durability tests, safety assessments, or other relevant criteria, depending on the nature of the product or service. Validation: Validation processes will be used to ensure that products and services are aligned with customer requirements and quality standards. This may involve customer sign-offs, product testing against specifications, and adherence to regulatory guidelines. Regular Monitoring: Regular monitoring of quality control processes will be conducted to track performance and identify trends. This continual assessment allows [COMPANY NAME] to detect quality issues early and take corrective actions promptly. Data Collection: Data related to quality control will be systematically collected, organized, and analyzed. This data may include information on product specifications, testing results, inspection reports, and customer feedback. Corrective Actions: In cases where deviations from quality standards are identified, corrective actions will be triggered. These actions may involve process adjustments, rework, or further testing to address and prevent quality issues. Corrective actions will be documented for future reference and process improvement. QUALITY ASSURANCE MEASURES

Easily Create Any Business Document You Need in Minutes.

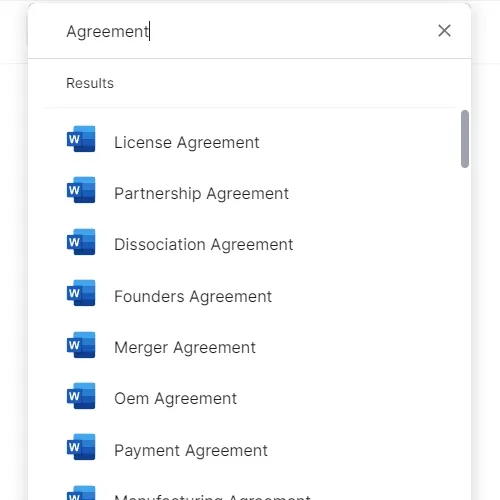

Access over 3,000+ business and legal templates for any business task, project or initiative.

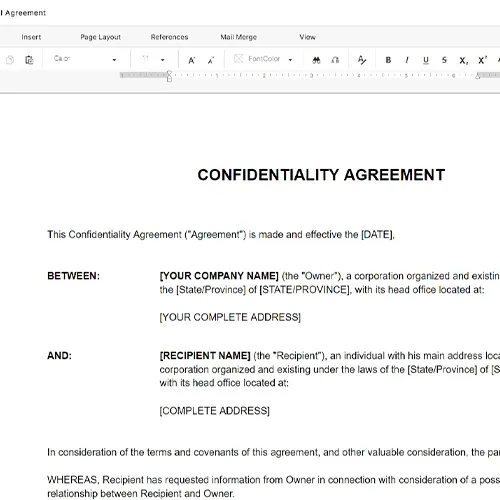

Customize your ready-made business document template and save it in the cloud.

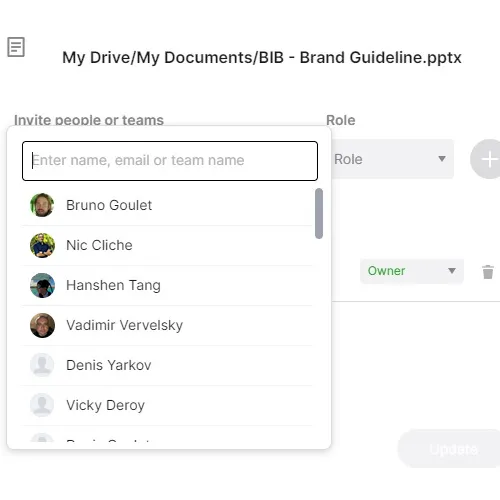

Share your files and folders with your team. Create a space of seamless collaboration.

Templates and Tools to Manage Every Aspect of Your Business.

Business in a Box Covers Every Business Department

Includes 16 Types of Business Documents You Need

and Achieve Your Business Goals Faster.