How to Manage Inventory in the Warehouse Template

Document content

This how to manage inventory in the warehouse template has 2 pages and is a MS Word file type listed under our business plan kit documents.

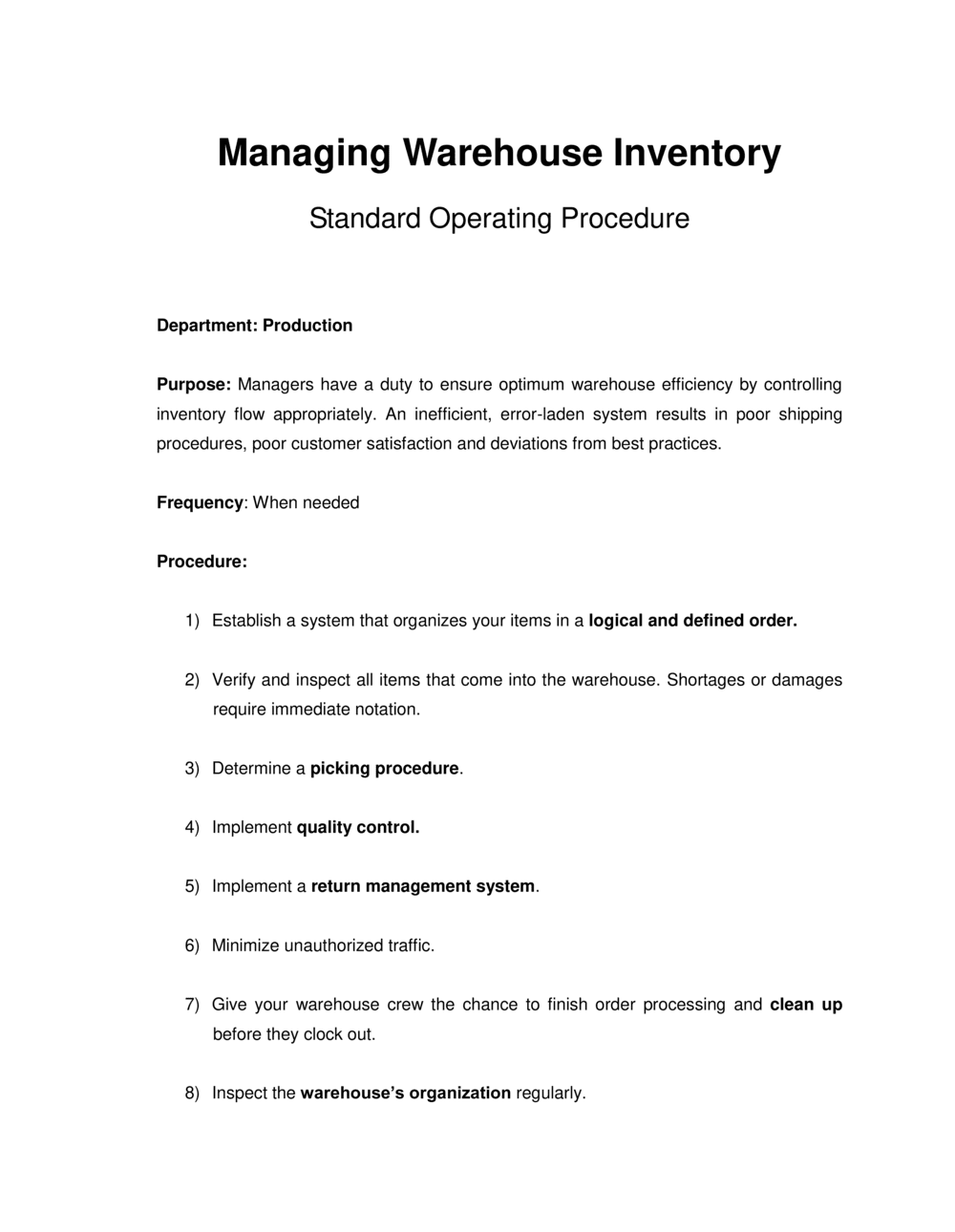

Sample of our how to manage inventory in the warehouse template:

Managing Warehouse Inventory Standard Operating Procedure Department: Production Purpose: Managers have a duty to ensure optimum warehouse efficiency by controlling inventory flow appropriately. An inefficient, error-laden system results in poor shipping procedures, poor customer satisfaction and deviations from best practices. Frequency: When needed Procedure: Establish a system that organizes your items in a logical and defined order. Verify and inspect all items that come into the warehouse. Shortages or damages require immediate notation. Determine a picking procedure. Implement quality control. Implement a return management system. Minimize unauthorized traffic. Give your warehouse crew the chance to finish order processing and clean up before they clock out. Inspect the warehouse's organization regularly. Definition/Explanation: Logical and defined order: Keep the high-volume items in front and center of the warehouse, closer to the shipping area. Picking procedure: This will help maintain pickup times and ensure all shipments leave the warehouse at the correct time. Quality control: The process usually involves checking a picked item against an order to make sure it's the correct SKU (stock keeping unit i.e

3,000+ Templates & Tools to Help You Start, Run & Grow Your Business

Document content

This how to manage inventory in the warehouse template has 2 pages and is a MS Word file type listed under our business plan kit documents.

Sample of our how to manage inventory in the warehouse template:

Managing Warehouse Inventory Standard Operating Procedure Department: Production Purpose: Managers have a duty to ensure optimum warehouse efficiency by controlling inventory flow appropriately. An inefficient, error-laden system results in poor shipping procedures, poor customer satisfaction and deviations from best practices. Frequency: When needed Procedure: Establish a system that organizes your items in a logical and defined order. Verify and inspect all items that come into the warehouse. Shortages or damages require immediate notation. Determine a picking procedure. Implement quality control. Implement a return management system. Minimize unauthorized traffic. Give your warehouse crew the chance to finish order processing and clean up before they clock out. Inspect the warehouse's organization regularly. Definition/Explanation: Logical and defined order: Keep the high-volume items in front and center of the warehouse, closer to the shipping area. Picking procedure: This will help maintain pickup times and ensure all shipments leave the warehouse at the correct time. Quality control: The process usually involves checking a picked item against an order to make sure it's the correct SKU (stock keeping unit i.e

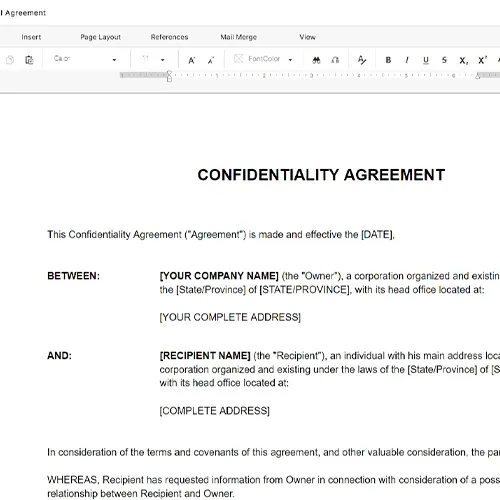

Easily Create Any Business Document You Need in Minutes.

Access over 3,000+ business and legal templates for any business task, project or initiative.

Customize your ready-made business document template and save it in the cloud.

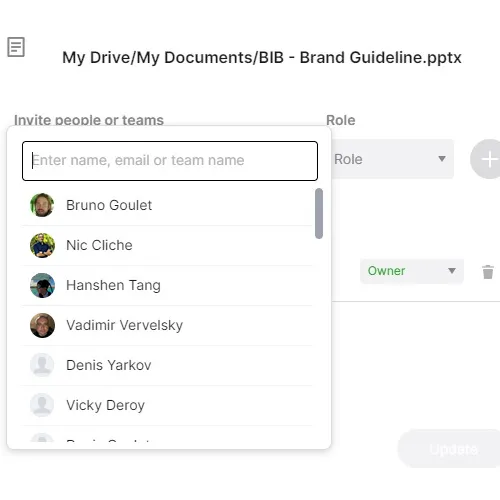

Share your files and folders with your team. Create a space of seamless collaboration.

Templates and Tools to Manage Every Aspect of Your Business.

Business in a Box Covers Every Business Department

Includes 16 Types of Business Documents You Need

and Achieve Your Business Goals Faster.